Research Factory for Small Satellites

13.01.2025

The ForFabSat project investigates how automation technologies, integrated testing procedures, and adaptive satellite design can make the series production of small satellites more efficient. The goal is the development and practical evaluation of manufacturing and testing processes that enable high-quality and scalable production. By analysing the manufacturing workflow, automation potentials are identified and transferred into a research production environment to optimise efficiency and throughput times in satellite manufacturing.

Project Goals

Europe currently has limited production capacity for large mega-constellations of small satellites. ForFabSat aims to transfer automation concepts from other industrial sectors to the space industry. This serves as a foundation for future large-scale production of small-satellite networks.

The research factory planned in ForFabSat is considered the starting point for future expansion stages. In this Phase 1, targeting a TRL of 3–5, the required infrastructure is being established, an initial production line implemented, and the first scientific investigations conducted.

Project Duration

October 2022 – December 2024

Selected Results

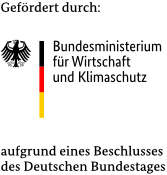

Implemented functional modules.

In Phase 1, the required infrastructure was successfully procured, installed, and put into operation, forming the basis for initial scientific investigations. These include a first robot-guided production line, facilities for rapid prototyping of subsystems, test equipment for space-environment simulations, distributed attitude-control testing setups, and the first conceptual design of a multi-satellite testing system.

Automated Manufacturing

In the field of automated production, a variety of functional modules were developed that can be flexibly used for tasks in satellite manufacturing. These modules ensure consistently high production quality and enable 24/7 operation. They include:

- Force-sensitive handling of satellite components (automated integration, instrumentation, material transport)

- Manufacturing processes (extendable robot tools for soldering, bonding, integration; in-process error correction)

- Inspection and measurement procedures (robot-guided optical inspection, measurement instruments)

- Complex test facilities (sun-sensor calibration, multi-satellite test setups)

- Mobile manipulators (flexible material flow, 24/7 operation of test stations, multi-satellite testing)

- Intuitive projection-based human–machine interface (process feedback projected into the workspace / onto components: progress, test results, errors, required interventions, assembly guidance; intuitive robot programming)

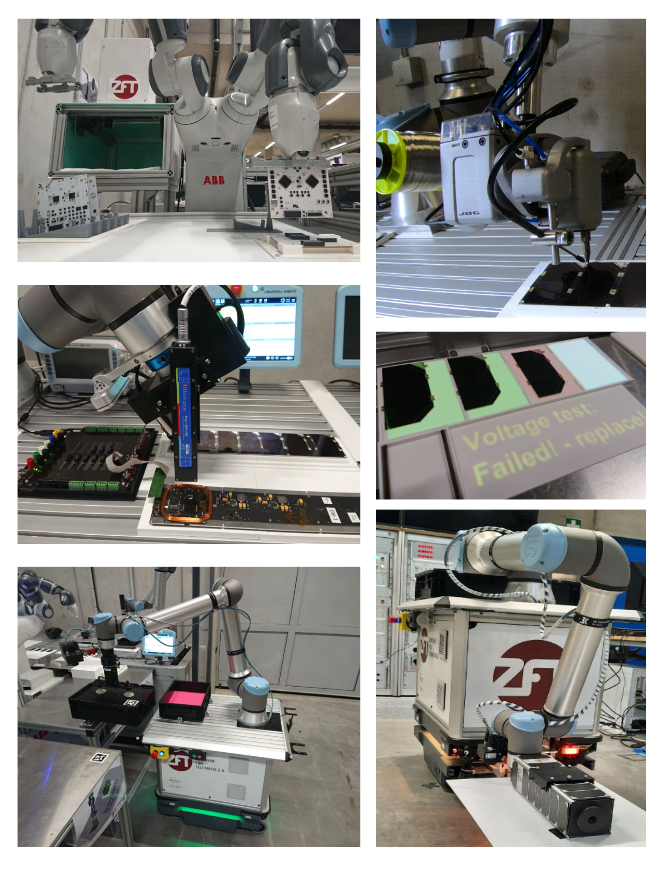

Hardware-in-the-Loop test of the attitude control system.

System Tests

Precise attitude control is essential for satellites—from solar panel pointing to precise Earth observation and communication. Within ForFabSat, a networked and distributed test system was implemented to evaluate a modular ADCS with sensors (sun sensors, magnetometers, star tracker, GNSS, IMU) and actuators (reaction wheels, magnetorquers, thrusters) under simulated space conditions.

Air-bearing platforms allow frictionless rotation, while an artificial sun, Helmholtz coil cage, and star-field simulator replicate realistic environmental conditions. High-precision rotary tables and mobile manipulators enable simulation of up to six degrees of freedom. Using a digital twin of the satellite or its subsystems, hardware-in-the-loop tests can be performed under authentic conditions.

Contact

We welcome your interest and are happy to answer any questions about this forward-looking project!

Please send inquiries to:

Funding

This project was funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) based on a resolution of the German Bundestag and supervised by the German Aerospace Center (DLR) as project management agency.